Tow Equipment

Complete tow dyeing project

GALVANIN S.p.A. produces complete tow dyeing project including:

LOADING SYSTEM OF DYEING CARRIER AND PRESS

Studied for the distribution of the tow inside the dyeing carrier placed in the press, it is composed of a retractable motorized trolley, where is installed an automatic loading arm. Together with the simultaneous rotation of the basket of the press, it places uniformly the material to be pressed in the dyeing carrier.

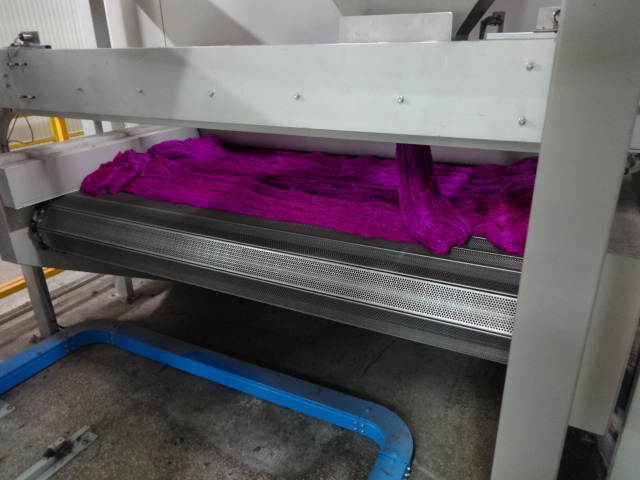

PADDER SYSTEM

To add chemicals before dryer.

DYEING MACHINE WITH BASKET

Vertical dyeing machines for tow with different capacities (from 5 kg to 1500 kg), complete with tanks for chemicals and dyestuff, air pad working function, differential pressure system, device for quick locking of the lid, external heat exchanger and sampling device. Machine can be supplied with preparation tank for the recuperation of the dyeing bath of the dyeing machine and for the preparation of the next dyeing cycle.